Sensitive biologics can destabilize if frozen or heated improperly, leading to unsafe and unusable last product or service. Also they are sensitive to various interactions within the lyophilization process which often can lead to the proteins to unfold, leading to lack of therapeutic performance for your patient2.

During the food stuff industry, lyophilization lessens the load of foods so which they’re a lot easier and less expensive to transport.

This paper gives in depth protocols for rat and mouse kidney, heart, liver, lung, and pores and skin tissue lyophilization, human peritoneal dialysis (PD) fluid concentration, together with drinking water and solvent removal from human fecal samples. We analyzed regardless of whether freeze-dried tissue samples could be saved at 4 °C for 20 months or more with out top quality impairment of RNAs and proteins.

Protocols for lyophilization and their efficacy for numerous samples. Representative graphs and reference protocols with precise time, temperature, and force values indicated for every section useful for: a kidney, coronary heart, liver, and lung tissue samples; b aorta and pores and skin tissue samples; c peritoneal dialysis fluid focus; d liquid elimination from fecal samples.

Other uncategorized cookies are people who are increasingly being analyzed and also have not been categorized right into a classification as however. Help you save & Take

JHS now has 8 lyophilizers Completely ready for website creation use, 7 at our Spokane facility and two at our Montreal facility, with ideas for a further lyophilizer available in 2025. Two more lyophilizers will likely be skilled by 2026 as part of our ongoing facility growth in Spokane and another in Montreal.

Pharmaceuticals and Biopharmaceuticals: As Earlier discussed, the delicacy of vaccines, therapeutic proteins, and various prescription drugs requires a preservation technique that makes certain potency and steadiness.

With many years of practical experience from the pharmaceutical industry, We all know exactly what a perfect infrastructure for your cryogenic freeze dryer requirements.

Mass transfer then occurs as being the sublimation progresses from your surface down as resistance to gasoline movement increases.

As the amount of advanced molecules in the drug growth pipeline improves, Progressively more products stand to gain from lyophilization. Any drug developer considering this manufacturing process need to be sure that they may have the combination of specialized understanding, facilities, and tools to realize accomplishment.

All factors and parts of your process has to be beautifully matched to the specific materials to prevent harm. This research requires a lyophilization pharmaceutical products great deal of your time and experience.

Cryoprotectants help maintain the structural integrity of your products by shielding drug material molecules towards drying stresses and, in the situation of biologics, support sustain conformation and forestall agglomeration. Bulking agents might also be added to your formulation to be sure a stable and stylish cake publish lyophilization.

Consuming a balanced diet regime that is lower in sugar might enable gradual indications of biological getting old, a whole new analyze suggests. Here is why.

Though lyophilization is taken into account a valuable, commercially validated process, In addition, it poses advanced formulation and producing challenges. The true secret troubles involve:

Shaun Weiss Then & Now!

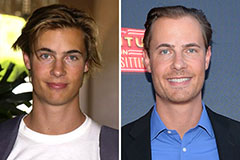

Shaun Weiss Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!